¿Qué es mejor para la contención, pasillo caliente o pasillo frío?

Release time: 2025-04-27

1. What are Cold Aisles & Hot Aisles Containment?

Cold aisle and Hot aisle configurations are energy-efficient designs for industrial data centers, optimizing air circulation to enhance cooling efficiency and reduce energy consumption. The core principle is to isolate the “cold air inlets” and “hot air outlets” of server racks, creating independent cold and hot aisles to prevent energy waste caused by mixed airflows. This “on-demand cooling” approach serves as a critical technology for carbon reduction in data centers.

2. Key Differences

Layout and Airflow Patterns

Cold Aisle: Racks are arranged face-to-face to form cold aisles. Chilled air from air conditioners enters the cold aisle through underfloor ducts or other pathways. Servers draw in cold air from the front, expelling internal heat through the equipment, and discharges it from the back. This design ensures direct and efficient delivery of cold air to server inlets, guaranteeing cooling performance.

Hot Aisle: Racks are arranged back-to-back to form hot aisles. Cold air is supplied from side walls, ceilings, or other openings, with servers drawing in air from the front or sides and expelling hot air into the hot aisle via rear vents. Hot air is then exhausted through top-mounted fans or dedicated return pathways to the AC system. This layout facilitates centralized hot air collection, reducing heat dispersion

Cooling Efficiency and Energy Consumption

| Metric | Cold Aisle | Hot Aisle |

| PUE Range | 1.1–1.3 (enclosed) | 1.5–1.8 (unenclosed) / 1.3–1.5 (enclosed) |

| Core Advantage | 30%+ cooling efficiency gain via airflow isolation | Improved efficiency when enclosed, but relies on auxiliary measures |

| Energy Case | 20% reduction in cooling energy after cold aisle enclosure | 0.3–0.5 PUE reduction after hot aisle retrofitting in traditional data centers |

Initial Investment and Operational Complexity

In initial investment and O&M, cold aisles need raised floors and enclosures, with higher upfront costs and more O&M work (e.g., duct maintenance, component faults), but long-term energy savings offset costs. Hot aisles require no raised floors, offer flexible layouts and lower initial costs, with simpler O&M focusing on exhaust airflow; incomplete closure may cause overheating, needing more temperature checks, suitable for budget-limited centers prioritizing convenience.

3. How to Choose?

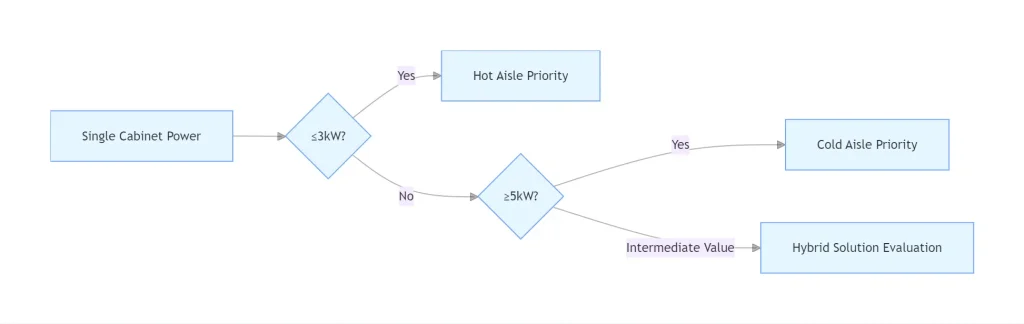

Based on Heat Load

- High Heat Load Scenarios (single rack power ≥5kW, uneven heat distribution): Cold aisles are preferred. Enclosed cold aisles enable precise air supply, balancing heat loads effectively. For example, AI computing centers with ≥10kW racks rely on cold aisle designs to ensure stable server operation and prevent performance degradation due to overheating.

- Uniform Heat Load Scenarios (single rack power ≤3kW): Hot aisles suffice whole-area air supply combined with negative pressure exhaust in hot aisles, using top-mounted axial fans, reduces construction costs by 40%+ in small-to-medium enterprise data centers (2–4kW racks).

Layout and Space Constraints

- Cold Aisles: Require 0.4–0.6m raised floors, demanding sufficient ceiling height. Unsuitable for low-ceiling retrofits in older buildings.

- Hot Aisles: Offer flexible layouts for irregular or space-constrained environments, adapting to diverse room shapes without excessive space use.

Budget Considerations

- Cold Aisles: Higher upfront costs but long-term energy savings make them suitable for well-funded projects prioritizing operational efficiency (e.g., financial institution data centers).

- Hot Aisles: Lower initial investment but potentially higher long-term energy use, ideal for budget-limited or temporary setups with lower energy cost sensitivity.

Operational Capability and Convenience

- Cold Aisles: Complex maintenance (e.g., underfloor ducts, enclosures) but offer cooler, cleaner front-side environments for safer equipment servicing, benefiting data centers with professional maintenance teams.

- Hot Aisles: Simplified maintenance focused on exhaust systems, enabling quick fault detection. Suitable for facilities with limited technical resources, though regular exhaust checks are required to avoid overheating.

So it’s not difficult to figure out how to choose! Cold aisles excel in high-density, energy-efficient environments, while hot aisles provide cost-effective flexibility for moderate-load scenarios.